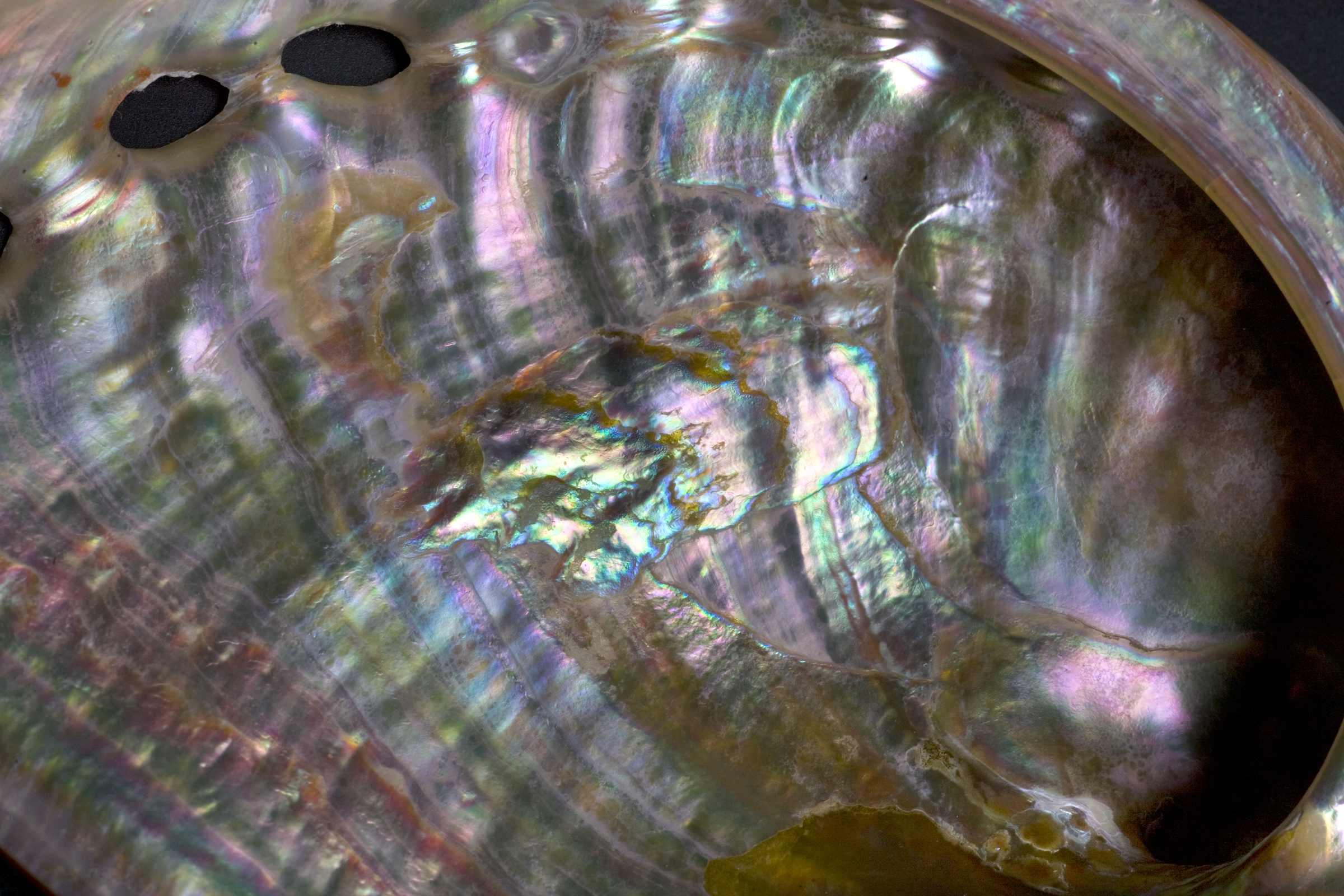

Scientists can learn a lot from natural material such as mother of pearl, or nacre, which have solved the conundrum of strength versus toughness. (Photo by Roy Kaltschmidt)

Videos on the Internet going viral are a weekly occurrence. Scientific review articles going viral in journals such as Nature are quite rare. “Bioinspired Structural Materials,” a comprehensive review article in Nature Materials that takes an in-depth look at the amazing structural and mechanical characteristics found in natural materials, received thousands of views and downloads in its first week on-line and those numbers continue to grow. The review was written by a team of Lawrence Berkeley National Laboratory (Berkeley Lab) scientists.

“The interest in this paper has been incredible,” says Robert Ritchie, a faculty scientist with Berkeley Lab’s Materials Sciences Division and the senior author of the review along with Antoni Tomsia, also with Berkeley Lab’s Materials Sciences Division. “We were hoping that our review would provide an inspiration for the current and future generation of scientists to seek breakthroughs in developing novel structural materials using nature’s guidelines. These guidelines can provide us with the scientific principles that will help us develop stronger and tougher structures.”

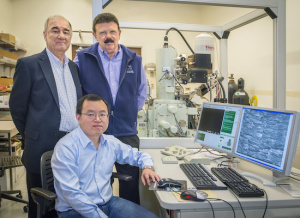

Tony Tomsia (left), Hao Bai (seated) and Rob Ritchie are unlocking the secrets behind the amazing structural and mechanical characteristics found in natural materials. (Photo by Roy Kaltschmidt)

Ritchie, who holds the H. T. and Jessie Chua Distinguished Professor of Engineering chair at the University of California (UC) Berkeley, is an internationally recognized authority on the mechanical behavior of materials. He and Ulrike Wegst, Associate Professor of Engineering at the Thayer School of Engineering at Dartmouth, are the review paper’s corresponding authors. Other co-authors, in addition to Ritchie, Tomsia and Wegst, are Hao Bai and Eduardo Saiz.

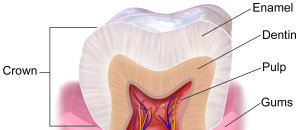

Despite working from a limited selection of components and at ambient temperature, nature has managed to craft a wide range of incredibly diverse materials with astonishingly elegant and complex architectures. Consider, for example, the tooth, which has managed to overcome the classic problem in materials design that the two key structural properties — strength and toughness — tend to be mutually exclusive: strong materials are usually brittle, whereas tough materials are usually weak.

Among the oldest forms of tissue in mammals, teeth are a product of 300 million years of evolution, a composition of enamel, which is the hardest substance in the human body but highly brittle, and dentin, a calcified tissue of mineralized collagen fibrils that is extremely tough thanks to a radial array of microscopic channels, called dentinal tubules. The junction where enamel and dentin meet, known as the DEJ, presents a crack-arrest barrier for flaws formed in brittle enamel.

The dentin underlying the hard but brittle enamel that coats a tooth provides a tough load-bearing base that prevents the tooth from fracturing when biting down. (Courtesy of Blausen Gallery)

“If the entire tooth were constructed from enamel, it would readily fracture,” says Ritchie. “However, the underlying dentin compensates for enamel’s brittleness by providing a tough load-bearing base. This is why teeth are able to withstand strong bite forces thousands of times per day and through millions of mastication cycles without failing, despite being unable to self-repair any damage.”

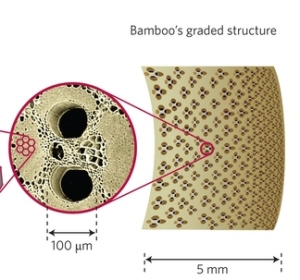

Another example is bamboo, which boasts a high-degree of structural strength through the combination of light weight, stiffness and a unique fiber-reinforced architectural structure.

“The distribution of load-bearing fibers in bamboo is not uniform but hierarchical so that fiber density is highest at the outer periphery where the stresses are largest,” says Tomsia. “By combining this density gradient with an optimized cellular microstructure tubular macroscopic shape, bamboo is two-to-four times more mechanically efficient than a beam with the same bending stiffness made from solid cell-wall material.”

Bamboo boasts high structural strength through the combination of light weight, stiffness and a unique fiber-reinforced architectural structure.

It is nature’s unique ability to combine the desirable properties of components into a material that performs significantly better than the sum of its parts that sparks strong interest in bioinspired materials design, the authors state. For example, nacre, or mother-of-pearl, the inner lining of the shells of abalone and certain other mollusks, is 95-percent aragonite, a hard but brittle calcium carbonate mineral. Yet nacre can be up to 3,000 times (in energy terms) more resistant to fracture than aragonite. No human-synthesized composite outperforms its constituent materials by such a wide margin.

“In the future, it is likely bioinspired structural materials will have broad applications in the current and future energy-saving landscape,” says Tomsia, who was part of a team, along with Ritchie and Saiz, that mimicked the structure of nacre to create one of the toughest ceramics ever produced.

“The biomedical field is a more likely and more immediate application,” Tomsia says, “but any application where you need light, strong, tough structures would benefit.”

A key to nature’s success at making materials is that the structural architectures deployed for any one type of material may vary lengths-of-scale that range from nanometers to micrometers. Human engineering has not been able to replicate these length scale variances so as to allow for manufacturing at high volume and low cost. While acknowledging that it remains an “open question” as to whether this challenge can be met, the review authors point to a number of laboratory successes that hold promise.

“It is important to note though that we are addressing structural materials and the timeline between developing them in the laboratory and their actual industrial use in cutting edge applications is measured not in a year or two, as is often the case for many functional materials, but in decades,” Ritchie says. “A point we make in the review is that we should not necessarily copy natural materials to the letter and replicate them exactly, but we should learn why natural materials work so well and see if we can implement these lessons in synthetic composites. That is what we mean by bioinspiration.”

# # #

Lawrence Berkeley National Laboratory addresses the world’s most urgent scientific challenges by advancing sustainable energy, protecting human health, creating new materials, and revealing the origin and fate of the universe. Founded in 1931, Berkeley Lab’s scientific expertise has been recognized with 13 Nobel prizes. The University of California manages Berkeley Lab for the U.S. Department of Energy’s Office of Science. For more, visit www.lbl.gov.