Note: This report was adapted from a University of Toronto press release. View the original release.

–By Tyler Irving

Researchers have created a new catalyst that brings them one step closer to artificial photosynthesis — a system that would use renewable energy to convert carbon dioxide (CO2) into stored chemical energy.

As in plants, their system consists of two linked chemical reactions: one that splits water (H2O) into protons and oxygen gas, and another that converts CO2 into carbon monoxide (CO). The CO can then be converted into hydrocarbon fuels through an established industrial process. The system would allow both the capture of carbon emissions and the storage of energy from solar or wind power.

Yufeng Liang and David Prendergast – scientists at the Molecular Foundry, a nanoscale research facility at the U.S. Department of Energy’s Lawrence Berkeley National Laboratory (Berkeley Lab) – performed theoretical modeling work used to interpret X-ray spectroscopy measurements made in the study, published Nov. 20 in Nature Chemistry. This work was done in support of a project originally proposed by the University of Toronto team to the Molecular Foundry, a DOE Office of Science User Facility.

“Carbon capture and renewable energy are two promising technologies, but there are problems,” said Phil De Luna of the University of Toronto, one of the leading authors in the latest study. “Carbon capture technology is expensive, and solar and wind power are intermittent. You can use batteries to store energy, but a battery isn’t going to power an airplane across the Atlantic or heat a home all winter: for that you need fuels.”

De Luna and his collaborators are designing an artificial system that mimics how plants and other photosynthetic organisms use sunlight to convert CO2 and water into molecules that humans can later use for fuel.

Phil De Luna of University of Toronto is one of the lead authors of a new study that reports a low-cost, highly efficient catalyst for chemical conversion of water into oxygen. The catalyst is part of an artificial photosynthesis system in development at the University of Toronto. (Credit: Tyler Irving/University of Toronto)

Last year, the team developed catalysts for such reactions. But while one of their catalysts worked under neutral conditions, the other required high pH levels in order to be most active. That meant that when the two were combined, the overall process was not as efficient as it could be: energy was lost when moving charged particles between the two parts of the system.

The team has now overcome this problem by developing a new catalyst for the first reaction – the one that splits water into protons and oxygen gas. Unlike the previous catalyst, this one works at neutral pH, and under those conditions it performs better than any other catalyst previously reported.

“It has a low overpotential, which means less electrical energy is needed to drive the reaction forward,” said Xueli Zheng, one of the study’s lead authors, who conducted the work as a PhD candidate at the University of Toronto and is now a postdoctoral scholar at Stanford University. “On top of that, having a catalyst that can work at the same neutral pH as the CO2 conversion reaction reduces the overall potential of the cell,” Zheng added. This reduces the amount of energy required of an external electrical source to assist in driving the reaction.

In the latest study, the team reported the overall electrical-to-chemical power conversion efficiency of the system at 64 percent. According to De Luna, this is the highest value ever achieved for such a system, including their previous one that reached 54 percent.

The new catalyst is made of nickel, iron, cobalt and phosphorus, all elements that are low-cost and pose few safety hazards. It can be synthesized at room temperature using relatively inexpensive equipment, and the team showed that it remained stable as long as they tested it, a total of 100 hours.

The team employed X-ray experiments at the Canadian Light Source and Berkeley Lab’s Advanced Light Source (ALS) to reveal the working principle behind this new catalyst, mainly focusing on the nickel chemistry during the reaction itself. The Theory Facility at Berkeley Lab’s Molecular Foundry specializes in the interpretation of such X-ray results, connecting chemical intuition to the atomic and electronic structure models of working materials.

At the ALS, researchers performed a technique known as X-ray absorption spectroscopy to verify the presence of a charged form of nickel (known as Ni4+) in the studied catalysts. “This work guided the team’s development of the high-performance catalysts,” said Jinghua Guo, an ALS scientist who assisted with the study. Guo said that the ALS and Canadian Light Source will also be used in continuing experiments related to the team’s development of new catalysts.

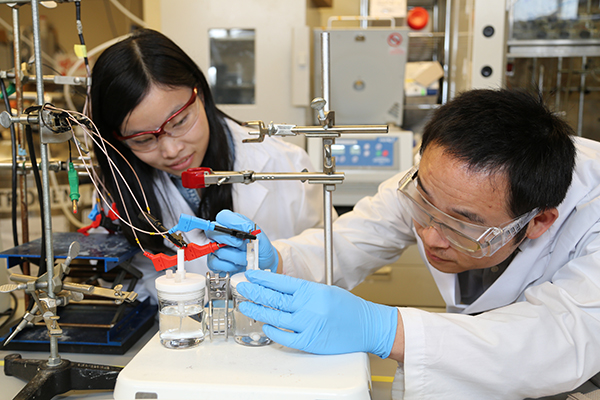

University of Toronto researchers Xueli Zheng, left, and Bo Zhang test a previous catalyst for the artificial photosynthesis system. The new catalyst works at lower pH, leading to an improvement in the overall efficiency of the system. (Credit: Marit Mitchell/University of Toronto)

Armed with their improved catalyst, the Toronto team is now working to build their artificial photosynthesis system at pilot scale. The goal is to capture CO2 from flue gas — for example, from a natural gas-burning power plant — and to use the catalytic system to efficiently convert it into liquid fuels.

“We have to determine the right operating conditions: flow rate, concentration of electrolyte, electrical potential,” De Luna said. “From this point on, it’s all engineering.”

He added, “Seeing the rapid advancement within the field has been extremely exciting.”

Other participants in this study were from the University of Toronto, Tianjin University and Fudan University in China, Brookhaven National Laboratory, and the Canadian Light Source Inc. The project was the result of an international and multidisciplinary collaboration. The Canadian Light Source in Saskatchewan provided the X-rays used to probe the electronic properties of the catalyst.

Portions of this work were performed at The Molecular Foundry, the National Energy Research Scientific Computing Center and the Advanced Light Source – all DOE Office of Science User Facilities at Berkeley Lab – and at the Center for Functional Nanomaterials, a DOE Office of Science User Facility at Brookhaven National Laboratory. The project was supported by the Natural Sciences and Engineering Research Council of Canada, the Canada Foundation for Innovation, Tianjin University, and the Beijing Light Source, and the U.S. Department of Energy Office of Science.