Contact: Paul Preuss, (510) 486-6249, [email protected]

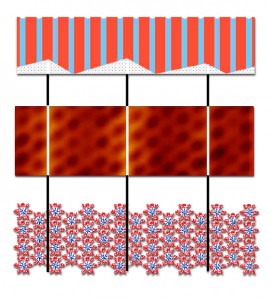

An overhead view (bottom) shows cylindrical block-coploymer structures, consisting of a central polymer (blue) linked to a surrounding polymer (red). An atomic-force microscope image (center), shows the densely packed cylinders, dark in the center, with the varying height of the surface beneath them visible as alternating lighter and darker stripes. The side view diagram (top) shows how the cylinders arrange themselves along the ridges of the crystalline facets. (Click on image for best resolution.)

In their narrowest dimensions, the magnetic domains that encode bits of information on today’s computer hard drives measure a couple of dozen nanometers, billionths of a meter, across. Imagine an array of bits each just three nanometers across, ten trillion of them in a square inch, densely packed and arranged in perfect order.

It was during the course of a long-distance phone call that Ting Xu of Lawrence Berkeley National Laboratory’s Materials Sciences Division (MSD) and Tom Russell of the University of Massachusetts Amherst came up with a key step in ordering such large, nanometer-scaled arrays. In the method Russell and Xu devised, which was subsequently demonstrated by members of Russell’s group, 10 trillion bits (10 terabits) of copolymer structures do most of the work – by assembling themselves. The researchers describe their work in the 20 February 2009 issue of the journal Science.

“Tom Russell’s laboratory has been working on polymer-based self-assembly for 20 years, concentrating for the last 10 years on one of the field’s great challenges, long-range order,” says Xu, a staff scientist in MSD and also an assistant professor in the Departments of Chemistry and Materials Science and Engineering at the University of California at Berkeley. “Long-range order means producing an ultradense array of patterned nanoelements covering a couple of square centimeters or more, where each element can be addressed.”

Self-assembly of polymers promises to vastly improve the properties and manufacturing processes of nanostructured materials, since self-assembly is highly parallel, quite versatile, and easy to implement. Especially promising are the novel compounds known as block copolymers, formed by two chemically different polymers that are linked together. Guided patterned arrays have been produced using electron-beam lithographic techniques or nanoimprint-lithography, but these methods are painstaking, and they have not yet been able to produce perfect surfaces over large areas.

“Tom and I discussed the many things that had been tried, and we knew it would very difficult if not impossible to generate features this small using photolithography,” Xu recalls of their phone conversation. “At that moment, something clicked. Crystals are naturally atomically ordered, and large single crystals are commercially available for many materials, including silicon and sapphire.”

Says Xu, “We knew that reconstructed surfaces of these single crystals produce facets – in other words, saw-toothed topographic patterns that are in registry with the underlying crystal over large distances.” They wondered if they could use this phenomenon to transfer the ordering of a single crystal at the atomic level to a block copolymer assembly on the scale of tens of nanometers.

The initial steps were simple: researchers in Russell’s group, led by postdoctoral fellow Soojin Park, chose large single crystals of sapphire cut at specific crystallographic planes. The featureless cut crystal was then heated to very high temperatures, 1300° to 1500° Celsius (ca. 2400° to 2700° Fahrenheit) and annealed for 24 hours. During heating and annealing, atoms exposed between the edges of the cross-cut planes rearranged themselves in the lattice, with the result that the surface of the crystal reconstructed itself as a series of parallel ridges, a sawtooth topography resembling, on the microscopic scale, that of the Western U.S.’s Basin and Range.

On this serrated surface, block copolymer thin films were allowed to self-assemble into nanoscopic cylinders standing upright from the surface of the sapphire. In microscope images the cylinders appear as hexagonally packed dots with arrangements readily directed by the parallel ridges of sapphire. Each cylinder in the array is a mere three nanometers in diameter, but the array extends over several square centimeters without a flaw, unguided by any pre-existing lithographic pattern.

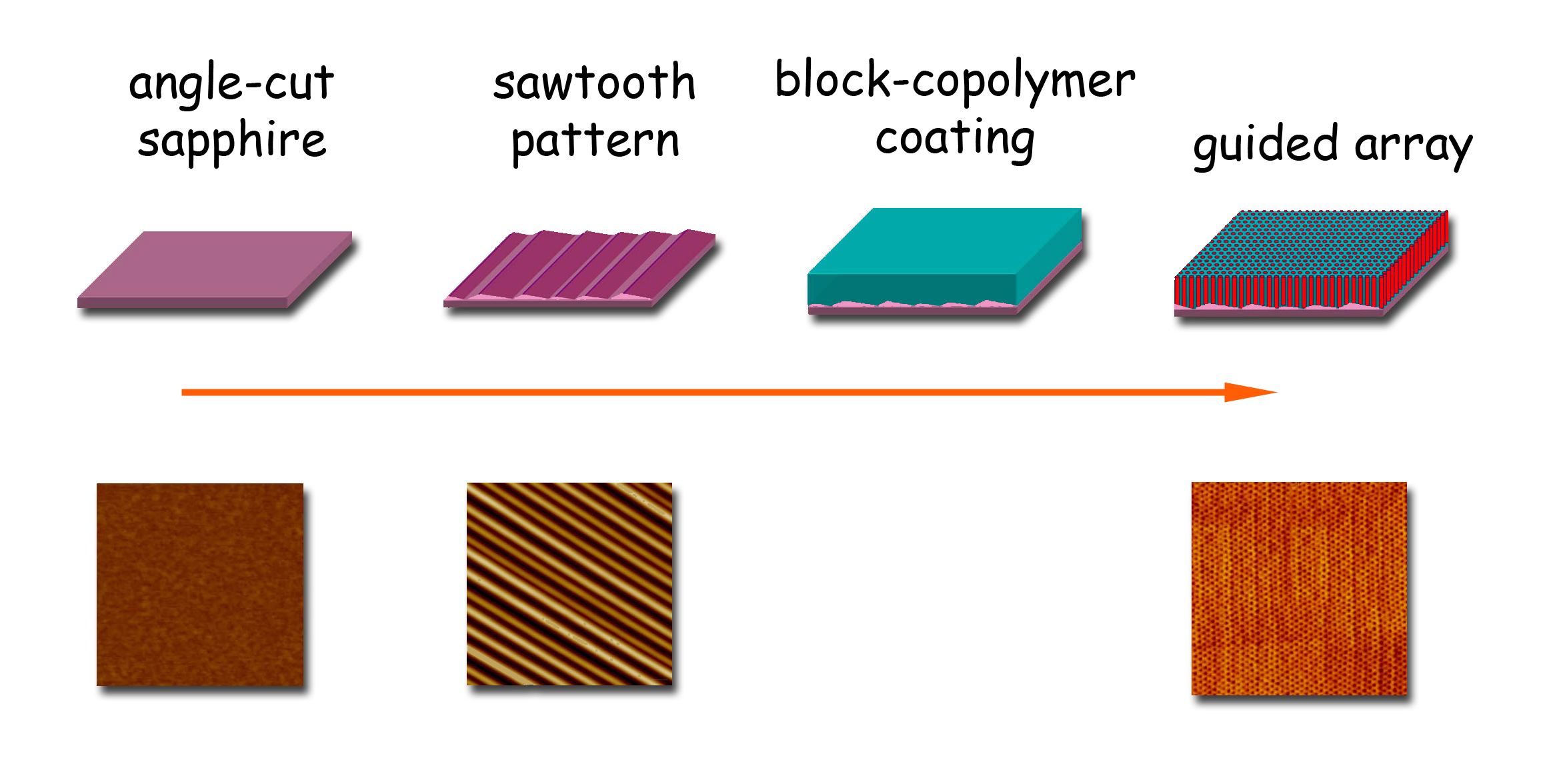

To generate long-range arrays of densely packed cyclindrical domains, the researchers began with single crystals of sapphire cut at an angle to the crystalline planes. The cut crystal was heated to over 1300° C and annealed in air for 24 hours to form saw-tooth patterns of parallel facets. A thin film of block copolymers was applied to the surface; chemical annealing produced an array of highly ordered, densely packed cylindrical domains extending across several square centimeters of the crystal. At bottom, atomic-force microscope images of the surface and copolymer array show the different stages. (Click on image for best resolution.)

The structures were analyzed by atomic force microscopy and by grazing-incidence small-angle x-ray scattering (GISAXS), performed at beamline 7.3.3 of Berkeley Lab’s Advanced Light Source – the first demonstration that GISAXS can provide a metric to characterize ordering on the nanoscopic scale over macroscopic distances.

“At first we were concerned that defects in the sapphire substrate could destroy the order of the array,” Xu says. “What we found was just the opposite. Although there are indeed many dislocations in the surface of the annealed crystal, the self-assembling film of copolymers maintained its perfectly hexagonal organization right over them, covering an area of a few square centimeters.”

From the atomic structure of the crystal lattice to nanometer-scale copolymer structures to centimeter-scale arrays is a wide span, amounting to perfection maintained over many orders of magnitude.

“The challenge is to get materials to talk over multiple scales,” says Xu. “An ideal scenario would be to throw a bunch of nanometer-scale Legos with all the properties you want into a box and shake it up. Let the molecular Legos assemble themselves into functional units without any complicated chemistry or processing. The focus of my group at Berkeley is to understand, and ideally control, the hierarchical self-assembly of complex systems.”

In nature, peptides and proteins are such complex, functional units, assembling themselves from amino acids strung together by molecular machines. Inspired by natural models, Xu’s group is working with synthetic peptides and artificial proteins, as well as with block copolymers and nanoparticles, to build new functional materials based on molecules designed with novel electronic, photonic, and biological properties.

Meanwhile, the achievement of a 10-terabit array of block copolymers formed in a single step on oriented crystal facets offers immediate practical promise. By treating the film of polymer structures with a solvent, the core polymer at the center of each cylinder is easily removed. The resulting thin film is a nanometer-sized sieve of a kind that could be used as a template for data storage or nanowires or other ordered nanoscopic structures for use in electronics or other devices.

Says Xu, “All the elements came together in this method – a good idea, a leader like Tom Russell with 20 years of experience in the field, a really good postdoc like Soojin Park to direct the experiment – and it worked. This one is going to make it to the market.”

Additional information

“Macroscopic 10-terabit-per-square-inch arrays from block copolymers with lateral order,” by Soojin Park, Dong Hyun Lee, Ji Xu, Bokyung Kim, Sung Woo Hong, Unyong Jeong, Ting Xu, and Thomas P. Russell, appears in the 20 February 2009 issue of Science and is available online to subscribers at http://www.sciencemag.org/cgi/content/full/323/5917/1030.

More about Ting Xu’s work in Berkeley Lab’s Materials Sciences Division is at http://www.lbl.gov/msd/programs/1md/4.1fs.html

More about the research of the Ting Xu Group at UC Berkeley is at http://www.mse.berkeley.edu/groups/xu/index.htm

More about Thomas Russell’s research at UMass Amherst is at http://www.pse.umass.edu/~trussell/