Contact: Lynn Yarris (510) 486-5375, [email protected]

The term “ionic liquid” may be largely unknown to the general public today but these salts that are liquids rather than crystals at room temperatures look to become far more familiar in the future as they are expected to play a starring role in the transformation of biomass into sustainable and carbon-neutral transportation fuels. Ionic liquids possess a unique capacity for dissolving lignocellulosic biomass and helping to hydrolyze the resulting liquor into sugars, but little has been known beyond that fact. Researchers with Berkeley Lab are part of a nationwide effort to learn more about ionic liquids and biomass. Their research is beginning to provide some valuable answers.

Chemical engineer Alexis Bell, a leading authority on catalysis, is leading a study into the application of ionic to the production of biofuels.

“Our challenge has been to understand what properties are required of ionic liquids for them to efficiently dissolve lignocellulose,” says Alexis Bell, a chemical engineer with joint appointments at Berkeley Lab and the University of California (UC) Berkeley, and a leading authority on catalysis. Bell and his group have been studying ionic liquids under a grant from the Energy Biosciences Institute (EBI), a partnership led by UC Berkeley that includes Berkeley Lab and the University of Illinois at Urbana-Champaign. The EBI is funded by BP.

In a recent talk at the American Chemical Society’s Spring 2009 national meeting in Salt Lake City, Bell described a study being carried out by he and his group into how ionic liquids dissolve lignocellulose and then depolymerize it into fermentable sugars. While this study is still young, the researchers have already identified potential ways of making the lignocellulose deconstruction process more efficient.

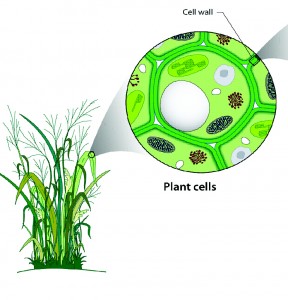

“If you look at a cell wall in a plant under a microscope you can see that it is comprised of three components – cellulose, hemicellulose and lignin,” Bell said. “The cellulose is bundled into crystalline fibrils that are surrounded by hemicellulose and wrapped in a sheath of lignin that makes the entire structure naturally recalcitrant (resistant to degradation).”

Among other objectives, Bell and his group are looking to determine how the composition of the ionic liquid affects the solubility of cellulose and lignin, how temperature affects the solubility of the sugars derived from the depolymenrization of cellulose, and how composition, temperature and co-solvent additions can affect the viscosity of cellulose/ionic liquid solutions.

“Viscosity is tremendously important because while ionic liquids are great solvents, the material dissolved in them flows like molasses and worse,” Bell said.

Working with the ionic liquid 1-butyl-3-methylimidazolium chloride or [BMIM][Cl], Bell and his group found that even at the boiling point of water – 100 degrees Celsius – the BMIM][Cl] will dissolve cellulose sugars without inducing any structural changes to the sugars. Bell and his team also found that temperatures could climb as high as 120 degrees Celsius before serious degradation of the cellulose structure occurs, significantly reducing the value of the dissolved product.

“When you dissolve the cellulose you put it into a form that bugs (such as yeast) can access for fermentation purposes,” Bell said. “At temperatures above 120 degrees Celsius, the ionic liquids we studied were acidic enough to form dark brown insoluble compounds that are technically called humins but what most chemists might call gunk.”

“When you dissolve the cellulose you put it into a form that bugs (such as yeast) can access for fermentation purposes,” Bell said. “At temperatures above 120 degrees Celsius, the ionic liquids we studied were acidic enough to form dark brown insoluble compounds that are technically called humins but what most chemists might call gunk.”

In testing the effects of ionic liquid composition on solubility, Bell and his group altered the types of cations and anions in their ionic liquid. They found that cellulose solubility depends on both the anion and the cation, and that chloride is the best anion while pyridinium appears to be the best cation.

In the viscosity tests, Bell and his colleagues found that dissolving sugars in [BMIM][Cl] greatly increases the viscosity of the ionic liquid, and that the addition of co-solvents such as acetonitrile or butyronitrile reduces viscosity without precipitating the sugars – a good thing.

“To do chemistry with these dissolved sugars we need to be able to stir them, which means we need viscosity but not too much viscosity,” said Bell. “We need to reduce the viscosity withour precipitatiting the cellulose. Acetonitrile and butyronitrile are co-solvents that can do the trick.”

Once the cellulose and hemicellulose components are dissolved, they must be depolymerized to sugars. For this Bell and his colleagues have tested various catalysts that promote the rearrangement of the sugar and removal of oxygen from it via hydrogenation. Among other results, they found that acids catalyze the isomerization of glucose to fructose and the conversion of fructose to furfurals. They also showed that the combined effects of an acid and a hydrogenation catalyst can lead to a broad spectrum of products and that the distributions of these products is governed by acid concentrations and hydrogen pressure.

Said Bell, “The hydrolysis of dissolved cellulose occurs readily in the presence of an acid catalyst, and the hydrogenolyis of glucose is promoted by a carbon-supported metal.”

Additional Information

For more on the research of Alexis Bell, visit his Website at http://www.cchem.berkeley.edu/atbgrp/

For more on the Energy Biosciences Institute, visit the Website at http://www.energybiosciencesinstitute.org/