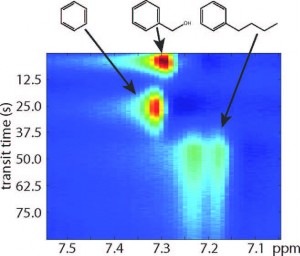

2-D plot shows separation of benzyl alcohol, benzene and butylbenzene using remote NMR/MRI with a monolithic chromatography column. Horizontal axis corresponds to the NMR chemical shift, vertical axis represents the transit time of compounds undergoing chromatographic separation.

By pairing an award-winning remote-detection version of NMR/MRI technology with a unique version of chromatography specifically designed for microfluidic chips, researchers with the U.S. Department of Energy (DOE)’s Lawrence Berkeley National Laboratory (Berkeley Lab) have opened the door to a portable system for highly sensitive multi-dimensional chemical analysis that would be impractical if not impossible with conventional technologies.

Alexander Pines, a faculty senior scientist in Berkeley Lab’s Materials Sciences Division and the Glenn T. Seaborg Professor of Chemistry at the University of California (UC) Berkeley, is one of the word’s foremost authorities on NMR (nuclear magnetic resonance) and its daughter technology, MRI (Magnetic Resonance Imaging). In this latest development, he led a collaboration in which a remote detection NMR/MRI technique that can rapidly identify the chemical constituents of samples in microfluidic “lab-on-a-chip” devices was used to perform analyses in a microscale monolithic chromatograph column.

“We have presented the first demonstration that a monolithic chromatograph column can be used to separate small molecules on a timescale that is compatible with NMR/MRI detection, an important first step to portable chromatographic devices,” says Vikram Bajaj, a project scientist in the Pines’ group who is the corresponding author of a paper describing this work in the journal Analytical Chemistry.

The Analytical Chemistry paper is titled “Remotely Detected NMR for the Characterization of Flow and Fast Chromatographic Separations Using Organic Polymer Monoliths.” Co-authoring the paper with Pines and Bajaj were Thomas Teisseyre, Jiri Urban†, Nicholas Halpern-Manners, Stuart Chambers and Frantisek Svec.

Chromatography is one of the indispensable tools of chemistry. By dissolving sample into a fluid – called the “mobile phase” – and flushing it through a solid medium – called the “stationary phase” – chemists can separate the sample’s constituent chemical species – called analytes – for identification and measurement, as well as for purification purposes. Analytes will be separated on the basis of how fast each individual species diffuses through the stationary phase.

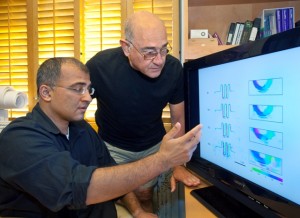

Vikram Bajaj (left) and Alexander Pines developed a remote NMR/MRI technology that received a 2011 R&D 100 Award. (Photo by Roy Kaltschmidt, Berkeley Lab)

“The coupling of our remote NMR/MRI technology with monolithic chromatography columns in a microfluidic chip enables us to obtain high resolution, velocity-encoded images of a mobile phase flowing through the stationary phase,” Bajaj says. “Our technique provides both real-time peak detection and chemical shift information for small aromatic molecules, and demonstrates the unique power of magnetic resonance, both direct and remote, in studying chromatographic processes.”

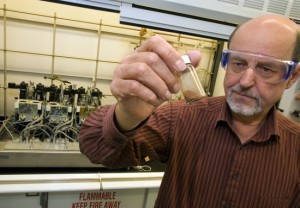

The coupling of remote NMR/MRI to chromatography was made possible by the polymer monolithic column, a technology developed by Analytical Chemistry paper co-author Frantisek Svec, a chemist who directs the Organic and Macromolecular Synthesis facility at Berkeley Lab’s Molecular Foundry, a DOE nanoscience center. In conventional chromatography, the stationary phase column is typically filled with porous polymer beads or some other discrete medium whose physical or chemical properties modulate the diffusion rates of analytes passing through. In Svec’s stationary phase, a chromatography column is filled with a monolithic solid polymer – meaning it is a single, continuous piece – that is perforated throughout with nanoscopic pores.

“Polymer monoliths as a separation media can be compared to a single large particle that does not contain inter-particular voids,” Svec says. “As a result, all the mobile phase must pass through the stationary phase as convective flow rather than diffusion during chromatographic processes. This convective flow greatly accelerates the rate of analyte separation.”

The remote NMR/MRI technology whose development was led by Pines won a 2011 R&D 100 Award. These awards, known as the “Oscars of Innovation,” recognize the year’s 100 most significant proven technological advances. Through a combination of remote instrumentation, JPEG-style image compression algorithms and other key enhancements, this remote NMR/MRI technology can zoom in on microscopic objects of interest within a sample flowing through the columns of a microfluidic chip with unprecedented spatial and time resolutions.

“Our remote NMR/MRI technology enables time-resolved imaging of multi-channel flow, dispenses with the need for large and expensive magnets for analysis, allows us to analyze complex and unprocessed mixtures in one pass, and adds portability to NMR/MRI,” Bajaj says.

Frantisek Svec, a chemist with Berkeley Lab’s Molecular Foundry, has developed unique polymer monoliths as a separation media for microfluidic chromatography. (Photo by Roy Kaltschmidt, Berkeley Lab)

The key to the success of remote NMR/MRI technology is the decoupling of the NMR/MRI signal encoding and detection phases. NMR/MRI signals arise from a property found in the atomic nuclei of almost all molecules called “spin,” which makes the nuclei act as if they were bar magnets with poles that point either “north” or “south.” Obtaining an NMR/MRI signal from a sample depends upon an excess of nuclear spins pointing in one direction or the other. In a conventional NMR/MRI set-up, in which the signal encoding and detection phases take place within one machine, this require the presence of a powerful external magnetic field. The remote NMR/MRI technology developed by Pines and his group, in which NMR?MRI signal encoding and detection are carried out independently, can detect NMR/MRI signals without the need of such a strong magnet, yet it still provides the same outstanding sensitivity of conventional NMR/MRI.

“With our remote NMR/MRI technology and the polymer monoliths of Frank Svec’s group, we were able to look inside optically opaque microfluidic columns and measure the velocity of the flowing fluid during a chromatographic separation,” Bajaj says. “We were also able to demonstrate in-line monitoring of chromatographic separations of small molecules at high flow rates.”

Results using the remote NMR/MRI technique with the polymer monoliths showed a much better ability to discriminate between different analytes at the molecular level, Bajaj says, than comparable analysis using spectrometry based on either mass or optical properties. This paves the way for multidimensional analysis, in which the result of a chromatographic separation would be encoded into an NMR/MRI signal by charge, size or some other factor and stored. The encoded fluid would then be run through a second separation and those results would also be encoded into an NRM/MRI signal and stored.

“This would allow us to create a multidimensional chromatography experiment that does not require the fluid volume to be physically partitioned,” Bajaj says. “The fluid would, quite literally, be partitioned in the magnetic degrees of freedom instead.”

This research was funded by the DOE Office of Science.

Lawrence Berkeley National Laboratory addresses the world’s most urgent scientific challenges by advancing sustainable energy, protecting human health, creating new materials, and revealing the origin and fate of the universe. Founded in 1931, Berkeley Lab’s scientific expertise has been recognized with 12 Nobel prizes. The University of California manages Berkeley Lab for the U.S. Department of Energy’s Office of Science. For more, visit www.lbl.gov.

Additional Information

For more information about the research of Alexander Pines and his group, visit the Web at http://waugh.qb3.berkeley.edu/

For more information about the Molecular Foundry visit the Website at http://foundry.lbl.gov/

For more about the research of Frantisek Svec, visit the Website at http://www.lbl.gov/msd/investigators/investigators_all/svec_investigator.html