Contact: Lynn Yarris (510) 486-5375, [email protected]

BERKELEY, CA – There is good news for the global effort to reduce the amount of lead in the environment and for the growing array of technologies that rely upon the piezoelectric effect. A lead-free alternative to the current crop of piezoelectric materials has been identified by researchers with the U.S. Department of Energy’s Lawrence Berkeley National Laboratory (Berkeley Lab) and the University of California (UC), Berkeley.

The key to this success is the use of bismuth ferrite, a compound with a perovskite crystal structure, meaning it has crystal planes of oxygen and bismuth atoms alternating with planes of oxygen and iron atoms. These planes can move relative to one other when the proper strain is applied. The research team discovered that the piezoelectric effect in bismuth ferrite becomes significantly enhanced in response to the application of epitaxial strain -compression in the direction of its crystal planes.

This high-resolution electron micrograph shows the the boundaries between rhombohedral (R phase) and tetragonal (T phase) regions – indicated by dashed lines - in a thin film of bismuth ferrite under epitaxial strain. A smooth transition between phases is observed with no dislocations or defects at the interface. The image was produced on TEAM 0.5 at the National Center for Electron Microscopy.

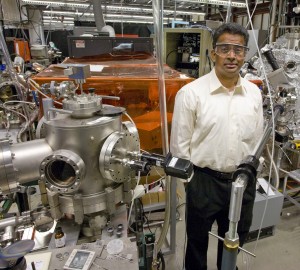

“We have demonstrated that epitaxial strain can be used to create a large piezoelectric responses in thin films of bismuth ferrite,” says Ramamoorthy Ramesh, a materials scientist who led this research. “The piezoelectric effect is reversible when the strain is relaxed.”

Ramesh holds joint appointments with Berkeley Lab’s Materials Sciences Division and UC Berkeley’s Department of Materials Science and Engineering and the Department of Physics. He is the senior author on a paper published in the journal Science entitled: “A Strain-Driven Morphotropic Phase Boundary in BiFeO3.”

Co-authoring the paper with Ramesh were Robert Zeches, Marta-Dacil Rossell, Jinxing Zhang, Alison Hatt, Qing He, Chan-Ho Yang, Amit Kumar, Chih-Hubng Wang, Alexander Melville, Carolina Adamo, Guang Sheng, Ying-Hao Chu, Jon Ihlefeld, Rolf Erni, Claude Ederer, Venkatraman Gopalan, Long-Qing Chen, Darrell Schlom, Nicola Spaldin and Lane Martin.

“In principle, the strain-driven piezoelectric effect we have observed in bismuth ferrite should be generic to other lead-free perovskites as well,” Ramesh says, “akin to chemically driven effects that are now well established in the manganites, cuprates and relaxors.”

Piezoelectric materials, as a result of their unique crystal structures, are able to couple mechanical and electrical properties. Place a mechanical strain on a piezoelectric and an electric charge is generated across its surface. Subject a piezoelectric to an electric charge and its shape becomes deformed. The electromechanical properties of piezoelectric materials have made them valuable components in a broad range of devices, including sensors, actuators and transducers. They are especially valuable for medical ultrasounds and for non-destructive testing of roads and bridges.

The most widely used piezoelectric materials today are lead-based perovskite compounds, especially lead zirconate titanate (PZT). These perovskites display superior piezoelectric properties in areas where the phase of their crystal structure abruptly changes. Such areas, known as morphotropic phase boundaries, are produced via complex chemical alloying of a PZT-type perovskite’s metal and oxide constituents. While the technology is well established, lead is a potent neurotoxin that poses a serious threat to human health, especially children, and to the environment.

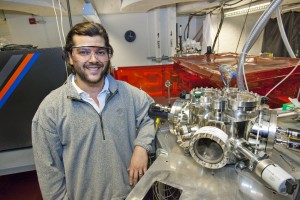

Robert Zeches, a member of Ramamoorthy Ramesh’s research group at UC Berkeley, showed that the application of a huge epitaxial strain to thin films of bismuth ferrite altered the material’s crystal structure to produce a significantly enhanced piezoelectric effect.(Photo by Roy Kaltschmidt, Berkeley Lab Public Affairs

“We have produced the piezoelectric effect by taking thin films of bismuth ferrite and applying a huge epitaxial strain,” says Robert Zeches, a member of Ramesh’s UC Berkeley research group who was the first author on the Science paper. “The bismuth ferrite wants to be in a rhombohedral phase but the epitaxial strain forces it into a tetragonal phase, creating a morphotropic phase boundary.”

If the strain is removed, the bismuth ferrite crystal structure reverts back to its original rhombohedral-like phase, Zeches says. By alternating between squeezing and relaxing, the researchers can shuttle the material back and forth between the two phases.

Ramesh joking observed that, “Inducing materials into such a schizophrenic state can be the key to obtaining exotic behavior.”

Ramesh and his group are now testing their strain-driven piezoelectric technique on other perovskites. They are also exploring the use of epitaxial strain to generate other phenomena such as magnetoresistance. Noting that the reversible phase changes in the bismuth ferrite films are accompanied by changes of a few nanometers in the height of the sample surface – a substantial change on this scale – Ramesh and his colleagues believe their results make bismuth ferrite an attractive candidate for data storage applications.

Ramamoorthy Ramesh, a faculty scientist with Berkeley Lab’s Materials Sciences Division, led the study in which a lead-free alternative to the current crop of piezoelectric materials was identified. (Photo by Roy Kaltschmidt, Berkeley Lab Public Affairs.)

The bismuth ferrite films and morphotropic phase boundaries created by epitaxial strain were characterized using TEAM 0.5, a unique transmission electron microscope created as part of the larger TEAM project. The acronym stands for Transmission Electron Aberration-corrected Microscope. TEAM 0.5 is capable of producing images with half angstrom resolution, which is less than the diameter of a single hydrogen atom. TEAM 0.5 and its successor, TEAM 1.0, are located at Berkeley Lab’s National Center for Electron Microscopy (NCEM) – a DOE national user facility and the country’s premier center for electron microscopy and microcharacterization.

“The resolution of TEAM 0.5, which is currently the highest in the world for an electron microscope, made it possible for us to image the atomic structure of both the tetragonal and rhombohedral phases and their interfaces,” says Ramesh.

This research was supported by the U.S. Department of Energy’s Office of Science.

Berkeley Lab is a U.S. Department of Energy national laboratory located in Berkeley, California. It conducts unclassified scientific research for DOE’s Office of Science and is managed by the University of California. Visit our Website at www.lbl.gov/

Additional Information:

For more information on the research of Ramamoorthy Ramesh, visit his Website at http://www.lbl.gov/msd/investigators/investigators_all/ramesh_investigator.html