Artificial photosynthesis is a dream technology that mimics a natural leaf, converting water and carbon dioxide into fuels with sunlight. But before this technology can take flight, scientists will have to solve a fundamental plumbing problem: how to gather molecules of fuel from microscopic reaction sites to pipes that will pour it out by the gallon.

Here again, researchers are taking a cue from nature. Following the same mathematical rules of “self-similarity” that govern the fractal shapes of snowflakes or determine the structure of blood vessels and capillaries, scientists at Berkeley Lab have shown how a single pipe can be subdivided into a network of microfluidic channels, or the reverse. This is the micro-plumbing needed to carry water and carbon dioxide to catalytic sites, where sunlight will split water, and hydrogen and oxygen are then channeled off separately; additional reactions can form hydrocarbon chains further downstream.

Kenny Lee, a graduate student in the Department of Mechanical Engineering at UC Berkeley, hit upon the “self-similarity” solution while working in the Fluid Mechanics Laboratory of Ömer Savaş. Both researchers are Berkeley Lab members of the Prototyping Group within the Joint Center for Artificial Photosynthesis (JCAP), a DOE Energy Innovation Hub. Lee built models using layers of tiles that carried identical patterns of grooves and holes; but in each layer, the tiles are precisely one quarter the size of those on the layer below.

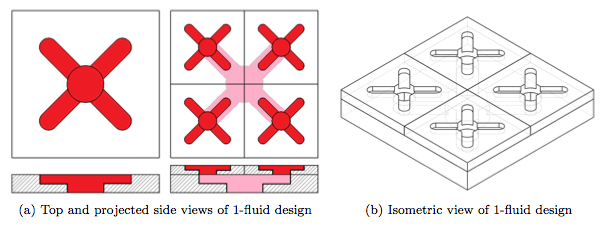

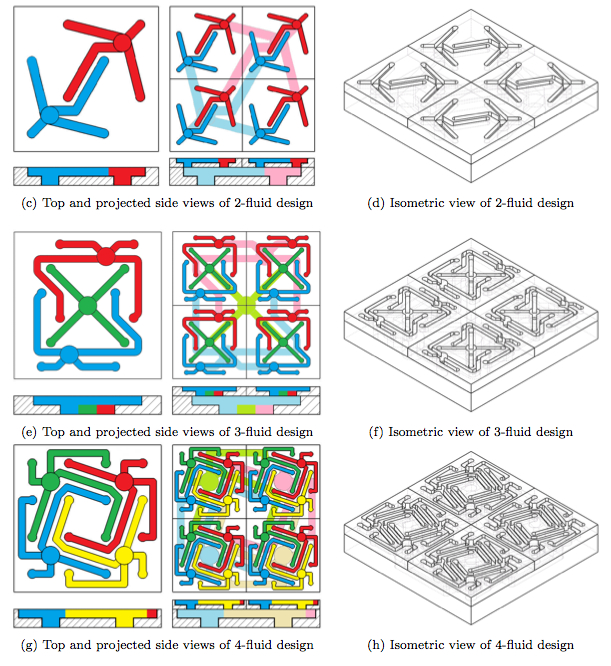

“The base layer is a single square tile containing the mother pattern; the second layer contains four daughter copies of the same, “self-similar” pattern.” Lee explains. “With each successive layer, the patterns remain identical, but the number of tiles increases geometrically while their size shrinks proportionally.”

Fluids transported through the Berkeley Lab devices travel in independent channels that narrow — in a stepwise, layered sequence — from macroscopic to microscopic scales. In reverse, the same layered design can move fluids through channels that widen from the microscale to macroscale.

Because of the self-similarity and symmetry of these designs, the holes in each layer are perfectly positioned to transport fluids from a single mother tile to the multiple daughter tiles in the next layer. The power of the design comes into play when more than one fluid channel is etched into the initial layer. As the geometries shrink, layer by layer, the integrity of each discrete fluid channel is retained, so that two, four, and perhaps many more separate channels can transport their liquids or gases from macro-to-micro, or micro-to-macro, while remaining isolated from each other.

The system is inherently scalable. In theory, it would be possible to build a system that carries fluids from pipes measured in meters to a network of capillaries measured in micrometers, or vice versa. Ultimately, this nature-inspired design system can be harnessed by engineers to build processes that improve on nature for production of sustainable fuels or the manufacture of complex molecules for industrial or medical applications.