Many of the common items we use in our everyday lives – from building materials to plastics to pharmaceuticals – are manufactured from fossil fuels. To reduce our reliance on fossil fuels and reduce greenhouse gas emissions, society has increasingly tried turning to plants to make the everyday products we need. For example, corn can be turned into corn ethanol and plastics, lignocellulosic sugars can be turned into sustainable aviation fuels, and paints can be made from soy oil.

But what if plants could be removed from the picture, eliminating the need for water, fertilizer, and land? What if microbes could instead be harnessed to make fuels and other products? And what if these microbes could grow on carbon dioxide, thus simultaneously producing valuable goods while also removing a greenhouse gas from the atmosphere, all in one reactor? Too good to be true?

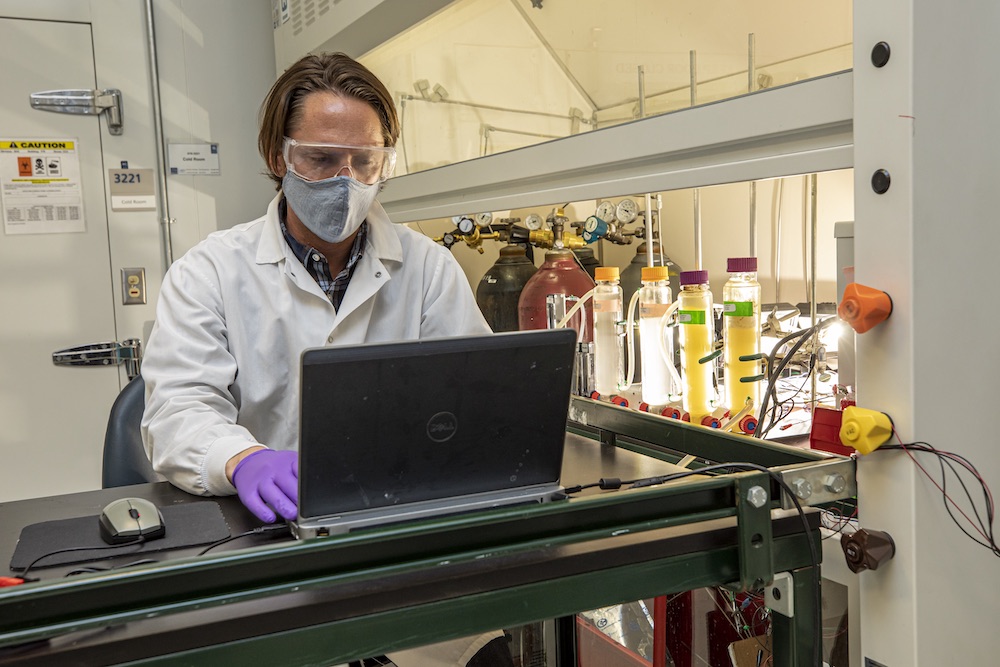

Berkeley Lab scientist Eric Sundstrom at the Advanced Biofuels and Bioproducts Process Development Unit (ABPDU). (Credit: Marilyn Sargent/Berkeley Lab)

Scientists at the Department of Energy’s Lawrence Berkeley National Laboratory (Berkeley Lab) have made good progress in turning this technology into reality. Led by scientist Eric Sundstrom, a research scientist at the Advanced Biofuels and Bioproducts Process Development Unit (ABPDU), and postdoctoral scholar Changman Kim, the project combines biology and electrochemistry to produce complex molecules, all powered by renewable energy. With carbon dioxide as one of the inputs, the system has potential to remove heat-trapping gases from the atmosphere, or in other words, a negative emissions technology (NET).

The scientific community as well as policymakers are reaching consensus that NETs can be an important tool in the fight against climate change by reducing the concentration of greenhouse gases in the atmosphere. Berkeley Lab researchers are pursuing a gamut of negative emissions technologies. (Read about “A Sponge to Soak Up Carbon Dioxide.”) Sundstrom’s project was launched two years ago under the Lab’s Laboratory Directed Research and Development (LDRD) program.

Q. How did this project start?

At the ABPDU, we work across a range of products. Virtually anything made by the chemical industry – you can find a way to use microbes to make those building block molecules, and then replace the petrochemical or even the agricultural equivalent of that product. There’s a lot of power to make virtually anything with biology. It’s just a question of whether it’s economical to do it.

A popular area for us right now is food proteins. For example, you might engineer a yeast to produce a milk protein. So, you can make chemically identical milk, but from yeast, so you’ve cut out the cow. We are helping companies that are making all kinds of products, from food proteins to biofuels to biobased skis, all using microbes. The common thread is that the vast majority of these companies use sugar, a relatively expensive and environmentally intensive material, as the primary feedstock.

So, we had an idea: can we do this same kind of biomanufacturing, but instead of using a plant-based carbon source, can we cut out the farm and directly use carbon dioxide as the carbon source for the microbe’s growth? And can we use electrons from renewable electricity to provide the necessary energy to generate the same suite of products?

Q. That sounds exciting but complicated. How exactly would that work? And what is this technology even called?

People call it different things. Electrons to products. Or electrons to molecules is popular. Or electrofuels.

We combine two steps to convert CO2 and electricity into bioproducts in a single reactor. This includes an electrochemical step – splitting water to produce hydrogen and oxygen – and a biochemical step, which is the microbial conversion of hydrogen, oxygen, and CO2 to biomass and ultimately products.

The tricky part is the microbes. Every microbe eats something in order to live, but very few microbes will eat electrons. So, can we convert electricity into something that microbes will readily eat? And so what we’re looking at is actually a very simple way of doing that: when you apply electric current across water at a certain voltage, the H2O splits into hydrogen and oxygen, and then the gases bubble out. And there are groups of bacteria that will consume hydrogen as their energy source, and then they’ll use carbon dioxide as their carbon source to grow. That part is relatively well known.

What we’re trying to do is combine those two processes. You have the electrodes in the water, bubbling out gas. And then we can add CO2. Now we have the three ingredients we need, hydrogen, oxygen, and CO2, all in the water, and then we can add microbes, all in one tank. By combining the electrochemical process with the microbial process, we can use the electrodes themselves to dissolve the gases into the bioreactor, simplifying the reactor design and saving a lot of energy. That’s the exciting part.

Berkeley Lab postdoctoral scholar Changman Kim at work on an electrons-to-molecules system at the conversion at the Advanced Biofuels and Bioproducts Process Development Unit at Lawrence Berkeley National Laboratory. (Credit: Marilyn Sargent/Berkeley Lab)

As part of the LDRD project, we optimized the electrolysis conditions and the microbial strain for mutual compatibility, and we set the system up to run on a solar panel. We also demonstrated that the microbes can be genetically engineered, so we can now produce complex molecules in a single tank, directly from photons and CO2.

Q. What kind of microorganisms do you use, and what were the challenges in getting this system to work?

The electrolysis creates a lot of unwanted stuff. It’s never 100% clean and efficient. You get things like hydrogen peroxide, or the electrodes themselves have metals in them that can come off and poison the biology. And so there are a lot of toxicity challenges that you have to overcome to make everything work together in one vessel.

The compatibility between the electrochemistry and the organism is important. The electrochemistry likes to be run at a really high or low pH and high temperature to get efficient hydrogen production. The previous work has pretty much all been with strains that are easy to work with in the lab, but maybe not the best choice for compatibility with these systems. So we’re looking at different microbes that thrive under extreme conditions, and that have natural resistance to certain kinds of toxicity.

What we’re focused on is trying to get as much electricity as possible, as efficiently as possible, into the bugs and get them to grow happily. We’ve done that. Now we’re starting to think about what we might be able to make, because once we have the bugs happy, then we can talk to the strain engineers, and they can start hacking away at the genes and instead of just growing, the microbes can make a product, such as fuel or building materials. We’ve now demonstrated that this kind of strain engineering is possible in our system for an example molecule, a natural pigment.

Q. What kind of products would these microbes make?

One of the reasons we like having the oxygen in there is that the organisms that grow with oxygen can produce a wide variety of things. You can make fat, you can make protein, you can make jet fuel directly. There’s a lot of cool biology you can do. And there are a lot of people at Berkeley Lab who specialize in genetically engineering these microbes. Berkeley Lab researchers have engineered things like methyl ketones, which are basically a direct diesel fuel replacement. So, we could literally just have one tank running off a solar panel – right now we have a desk lamp shining on the solar panel – we put CO2 in, and once the microbes are engineered, you would get diesel fuel, just rising to the top of the tank. You can skim that off. It’s a very clean, simple kind of a process.

Q. How would this work in a real-world setting?

That’s a question that the DOE is just starting to really dig in on – where would you put this? You want a concentrated source of CO2, and you also want a low-cost source of renewable energy, be it solar, wind, or hydro. A lot of the current thinking is around ethanol plants in the Midwest, where there’s wind power, and the CO2 from ethanol plants is almost totally pure. And an ethanol plant already has equipment for doing biology and chemical separations.

Q. How do you envision this technology fitting into the climate change fight?

We need to start pulling CO2 out of the atmosphere faster. Instead of carbon capture and storage, these things offer carbon capture and utilization, which provides an economic driver to pull that CO2 out of the atmosphere instead of just, say, pumping it underground.

I think electrons-to-molecules technology in general is going to be an answer to electrifying the last few segments of the economy that are still going to be relying on fossil fuels. It’s hard to electrify a long-haul jet plane, or a rocket, or a ship. But if you can make the fuel with electricity, that’s one way to electrify the rest of transportation.

I don’t want to make it seem like biology is the only the only way to do this. But I think biology is an important way to do this and that biological conversion can produce products with a specificity that the other approaches really can’t match. I think there is potential to move the bioeconomy in general away from any agricultural feedstocks and onto electricity, which would be a really exciting long-term prospect.

# # #

Founded in 1931 on the belief that the biggest scientific challenges are best addressed by teams, Lawrence Berkeley National Laboratory and its scientists have been recognized with 14 Nobel Prizes. Today, Berkeley Lab researchers develop sustainable energy and environmental solutions, create useful new materials, advance the frontiers of computing, and probe the mysteries of life, matter, and the universe. Scientists from around the world rely on the Lab’s facilities for their own discovery science. Berkeley Lab is a multiprogram national laboratory, managed by the University of California for the U.S. Department of Energy’s Office of Science.

DOE’s Office of Science is the single largest supporter of basic research in the physical sciences in the United States, and is working to address some of the most pressing challenges of our time. For more information, please visit energy.gov/science.