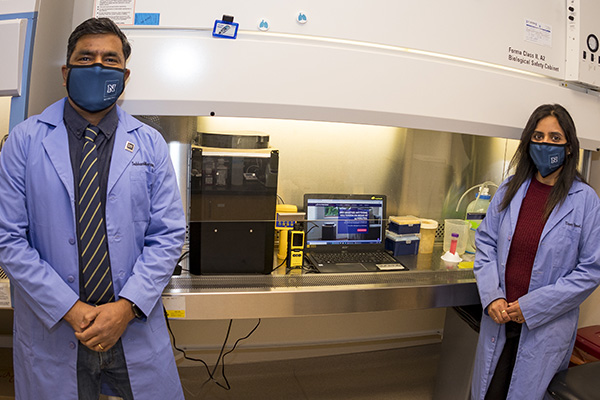

Subhash Verma, associate professor of microbiology and immunology (left) and Timsy Uppal, research scientist, department of microbiology and immunology (right), conducted experiments at the University of Nevada, Reno.

Ending the COVID-19 pandemic will require many things — widespread vaccine rollout and treatment options, as well as a stable supply of personal protective equipment (PPE) like N95 face masks and plastic face shields. Today, most PPE is used only once, which has created an unsustainable strain on production lines and a massive spike in landfill loads.

Current methods to decontaminate PPE, like ultraviolet germicidal irradiation, heat sterilization, and chemical disinfectants, are successful at eradicating the virus but compromise the PPE material, ultimately increasing the wearer’s potential exposure to pathogens.

Antoine Snijders, a staff scientist at Berkeley Lab, and collaborators at the University of Nevada, Reno (UNR) School of Medicine have confirmed that under the conditions tested, a new dry-sanitizing device may provide a safe and reliable solution that doesn’t alter the integrity of the PPE material. They reported their results in the journal Pathogens.

Snijders worked with his UNR colleagues to design the experiments that evaluated the efficacy of this device on N95 face masks (made of a porous material) and face shields (made from nonporous material). The device, about the size of a medium-sized trash bin, uses air pressure and ionization to decontaminate viruses and bacteria. Both forms of PPE were exposed to a close genetic model of the SARS-CoV-2 virus and put inside the device for 15 minutes. Subsequent tests indicated that the virus had been successfully inactivated on both materials.

Snijders’s contribution to the research was supported by the Department of Energy’s Office of Technology Transitions.

Read the UNR press release.