Contact: Lynn Yarris (510) 486-5375, [email protected]

Biomimicry – technological innovation inspired by nature – is one of the hottest ideas in science but has yet to yield many practical advances. Time for a change. Scientists with the U.S. Department of Energy’s Lawrence Berkeley National Laboratory (Berkeley Lab) have mimicked the structure of mother of pearl to create what may well be the toughest ceramic ever produced.

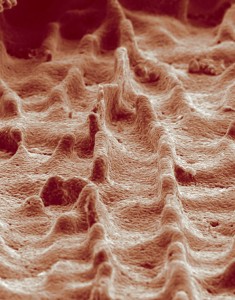

The roughness of the alumina/PMMA hybrid ceramic controls the strength of the interfaces, which is critical in determining the material’s overall toughness as it affects the sliding process in the polymeric "mortar" layers.

Through the controlled freezing of suspensions in water of an aluminum oxide (alumina) and the addition of a well known polymer, polymethylmethacrylate (PMMA), a team of researchers has produced ceramics that are 300 times tougher than their constituent components. The team was led by Robert Ritchie, who holds joint appointments with Berkeley Lab’s Materials Sciences Division and the Materials Science and Engineering Department at the University of California, Berkeley.

“We have emulated nature’s toughening mechanisms to make ice-templated alumina hybrids that are comparable in specific strength and toughness to aluminum alloys,” says Ritchie. “We believe these model materials can be used to identify key microstructural features that should guide the future synthesis of bio-inspired, yet non-biological, light-weight structural materials with unique strength and toughness.”

The results of this research were reported in the December 5, 2008 issue of the journal Science, in a paper entitled:“Tough, bio-inspired hybrid materials.” Co-authoring the paper with Ritchie were Etienne Munch, Max Launey, Daan Hein Alsem, Eduardo Saiz and Antoni Tomsia.

Naturally Tough

Mother of pearl, or nacre, the inner lining of the shells of abalone, mussels and certain other mollusks, is renowned for both its iridescent beauty and its amazing toughness. Nacre is 95-percent aragonite, a hard but brittle calcium carbonate mineral, with the rest of it made up of soft organic molecules. Yet nacre can be 3,000 times (in energy terms) more resistant to fracture than aragonite. No human-synthesized composite outperforms its constituent materials by such a wide margin. The problem has been that nacre’s remarkable strength is derived from a structural architecture that varies over lengths of scale ranging from nanometers to micrometers. Human engineering has not been able to replicate these length scale variances.

In the "brick-and-mortar" phase of the alumina/PMMA hybrid, aragonite "bricks" slide past each other to dissipate strain energy while the polymer "mortar" acts as a lubricant.

Two years ago, however, Berkeley Lab researchers Tomsia and Saiz found a way to improve the strength of bone substitutes through a processing technique that involved the freezing of seawater. This process yielded a ceramic that was four times stronger than artificial bone. When seawater freezes, ice crystals form a scaffolding of thin layers. These layers are pure ice because during their formation impurities, such as salt and microorganisms, are expelled and entrapped in the space between the layers. The resulting architecture roughly resembles that of nacre.

“Since seawater can freeze like a layered material, we allowed nature to guide the process by which we were able to freeze-cast ceramics that mimicked nacre,” said Tomsia when this research was reported.

Engineered to be Tough

In this latest research, Ritchie, working with Tomsia and Saiz, refined the freeze-casting technique and applied it to alumina/PMMA hybrid materials to create large porous ceramic scaffolds that much more closely mirrored the complex hierarchical microstructure of nacre. To do this, they first employed directional freezing to promote the formation of thin layers (lamellae) of ice that served as templates for the creation of the layered alumina scaffolds. After the ice was removed, spaces between the alumina lamellae were filled with polymer.

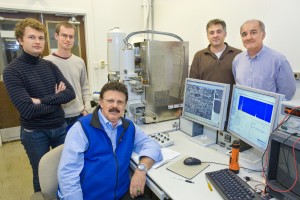

Robert Ritchie (seated) led a research effort in which the microstructure of mother of pearl was mimicked to create what may well be the toughest ceramic ever produced. Collaborating with Ritchie were (from left) Maximilien Launey, Daan Hein Alsem, Eduardo Saiz and Antoni Tomsia.

“The key to material toughness is the ability to dissipate strain energy,” says Ritchie. “Infiltrating the spaces between the alumina layers with polymer allows the hard alumina layers to slide (by a small amount) over one another when load is applied, thereby dissipating strain energy. The polymer acts as a lubricant, like the oil in an automobile engine.”

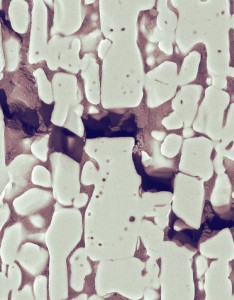

In addition to making the lamellar scaffolds, the team was also able to fabricate nacre-like “brick-and-mortar” structures with very high alumina content. They did this by collapsing the scaffolds in a perpendicular direction to the layers then sintering the resulting alumina “bricks” to promote brick densification and the formation of ceramic bridges between individual bricks.

Says Saiz, “Using such techniques, we have made complex hierarchical architectures where we can refine the lamellae thickness, control their macroscopic orientation, manipulate the chemistry and roughness of the inter-lamellae interfaces, and generate a given density of inorganic bridges, all over a range of size-scales.”

Next Step

For ceramic materials that are even tougher in the future, Ritchie says he and his colleagues need to improve the proportion of ceramic to polymer in their composites. The alumina/PMMA hybrid was only 85-percent alumina. They want to boost ceramic content and thin the layers even further. They also want to replace the PMMA with a better polymer and eventually replace the polymer content altogether with metal.

Says Ritchie, “The polymer is only capable of allowing things to slide past one another, not bear any load. Infiltrating the ceramic layers with metals would give us a lubricant that can also bear some of the load. This would improve strength as well as toughness of the composite.”

Such future composite materials would be lightweight and strong as well as tough, he says, and could find important applications in energy and transportation.

This research was supported by DOE’s Office of Science, through the Division of Materials Sciences and Engineering in the Basic Energy Sciences office.

Berkeley Lab is a U.S. Department of Energy national laboratory located in Berkeley, California. It conducts unclassified scientific research and is managed by the University of California. Visit our Website at www.lbl.gov/