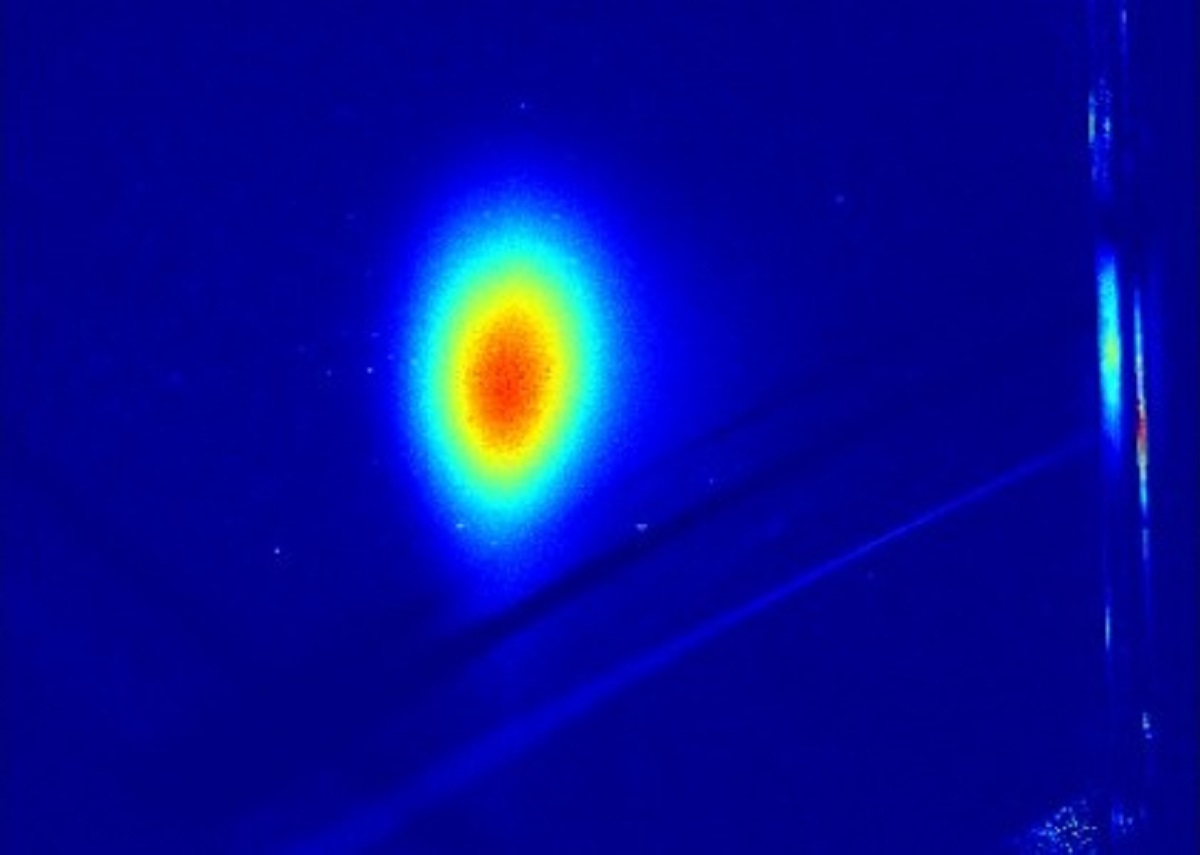

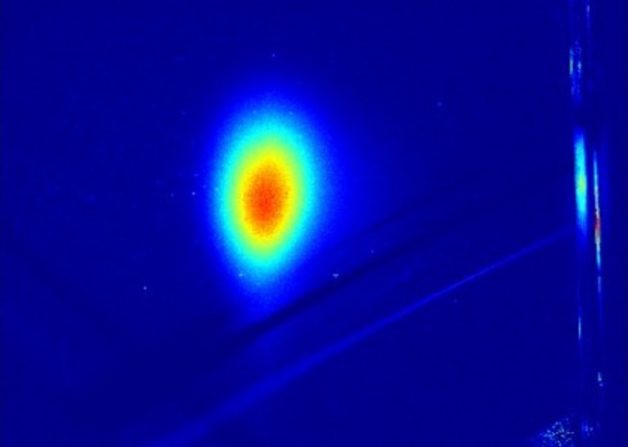

Image of the first beam of photoelectrons for a next-generation LCLS-II X-ray laser housed at SLAC. Berkeley Lab designed and built the electron gun supplying the laser’s electrons. (Credit: SLAC National Accelerator Laboratory)

This press release was adapted from the original release published by SLAC National Accelerator Laboratory. View the original release.

A new electron gun, designed and built at the U.S. Department of Energy’s Lawrence Berkeley National Laboratory (Berkeley Lab) to supply electrons for a next-gen X-ray laser at SLAC National Accelerator Laboratory in Menlo Park, California, has fired its first electrons. The X-ray laser is part of the LCLS-II project, which is an upgrade of SLAC’s Linac Coherent Light Source (LCLS) X-ray laser.

Located at the front end of LCLS-II, the gun is part of the injector that will generate a nearly continuous stream of electrons to drive the production of powerful X-ray beams at a pulse rate 8,000 times faster than the typical 120-pulses-per-second rate for the original LCLS X-ray free-electron laser.

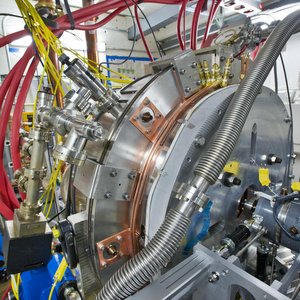

Berkeley Lab Mechanical Engineers Joe Wallig, left, and Brian Reynolds work on the final assembly of the LCLS-II injector gun in a specially designed clean room at Berkeley Lab in August. (Credit: Marilyn Chung/Berkeley Lab)

The successful production of electrons on Wednesday was the culmination of 15 months of work, during which teams have installed and tested parts of the injector at SLAC, building on design and testing work at Berkeley Lab.

“This is a critical milestone for the LCLS-II project, and for the Berkeley Lab team that designed and built the gun and low-energy beam transport for the project,” said John Corlett, who serves as Berkeley Lab’s interim project management officer and has also served as the senior team lead for Berkeley Lab’s contributions to the LCLS-II project.

Building a Better Electron Gun

The successful test of the LCLS-II electron gun marks the culmination of an R&D effort spanning more than a decade at Berkeley Lab.

The gun’s design was conceived in 2006 by John W. Staples, a retired Berkeley Lab physicist, and Fernando Sannibale, a senior scientist in Berkeley Lab’s Accelerator Technology and Applied Physics Division. Soon after, work began on a prototype electron gun known as Advanced Photoinjector EXperiment that would later become the prototype for the LCLS-II electron gun.

SLAC accelerator physicist Feng Zhou, who is in charge of LCLS-II injector commissioning, said the latest milestone in producing electrons “shows the complex injector system is working and that allows us to begin the crucial task of optimizing its performance.” He added, “The injector is a very critical system because the quality of the electron beam it creates has a huge effect on the quality of X-rays that will ultimately come out of LCLS-II.”

The injector was delivered from Berkeley Lab to SLAC on Jan. 22, 2018 (see related article). During assembly, the injector underwent a rigorous cleaning process at Berkeley Lab to minimize the possible contaminants — tiny traces of dust and other particulates could affect the electron gun’s performance. Since delivering the hardware systems to SLAC, the Berkeley Lab team has had continuing involvement in preparing for the startup of the injector.

Making X-rays with electrons

X-ray lasers use pulsed beams of electrons to generate their X-ray light. These beams gain tremendous energy in massive linear particle accelerators and then give some of that energy off in the form of extremely bright X-ray flashes when they fly through special magnets known as undulators.

The injector’s role is to produce an electron beam with high intensity, a small cross-section and minimal divergence, the right pulse rate, and other properties required to achieve the best possible X-ray laser performance.

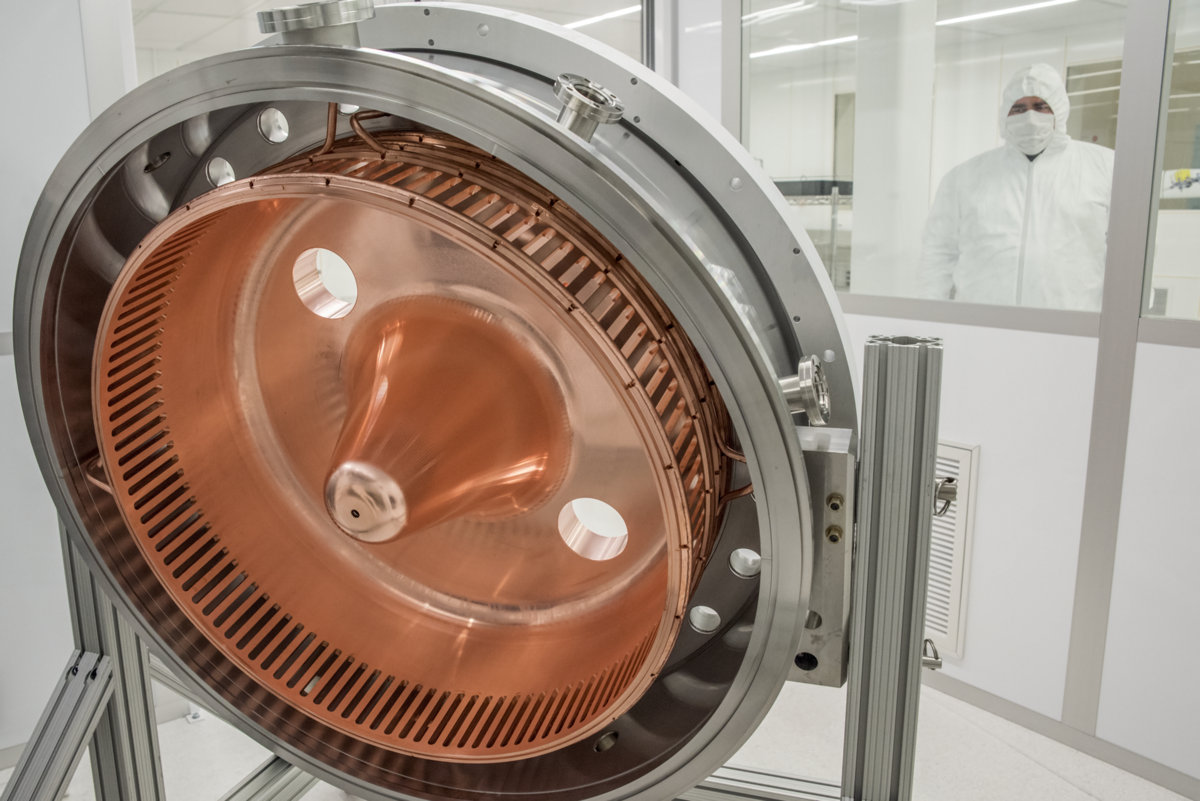

The electrons fired by the injector come from the electron gun. It consists of a hollow metal cavity where flashes of laser light hit a photocathode that responds by releasing electrons. The cavity is filled with a radiofrequency (RF) field that boosts the energy of the freed electrons and accelerates them in bunches toward the gun’s exit.

Magnets and another RF cavity inside the injector squeeze the electrons into smaller, shorter bunches, and an accelerator section, to be installed over the next few months, will increase the energy of the bunches to allow them to enter the main stretch of the X-ray laser’s linear accelerator. Spanning almost a kilometer in length, this superconducting accelerator will increase the speed of the electron bunches to almost the speed of light.

Berkeley Lab researchers are also responsible for overseeing the production and delivery of the undulators, developing the low-level RF controls, and performing troubleshooting for hardware and related systems for the LCLS-II project. The team is also looking forward to participating in the physics studies and optimization of the electron beam for the upgrade project, Corlett said.

The production of “soft X-ray” or lower-energy X-ray laser undulators for the LCLS-II project is now complete, and production of “hard X-ray” or higher-energy X-ray laser undulators is expected to be completed later this year, he added.

A copper cone structure inside the injector gun’s central cavity. (Credit: Marilyn Chung/Berkeley Lab)

The million-pulse challenge

The most delicate injector component is the electron gun, and for LCLS-II the technical demands are bigger than ever, said John Schmerge, deputy director of SLAC’s Accelerator Directorate.

“The first generation of LCLS produced 120 X-ray flashes per second, which means the injector laser and RF power only had to operate at that rate,” he said. “LCLS-II, on the other hand, will also have the capability of firing up to a million times per second, so the RF power needs to be switched on all the time and the laser has to work at the much higher rate.”

This creates major challenges.

First, the continuous RF field produces a lot of heat inside the cavity. Operating at 80 kilowatts – the equivalent of about 80 microwave ovens continuously operating at 1,000 watts – this heat, if unchecked, could damage the electron gun and degrade its performance.

To handle the large amount of power, the LCLS-II gun is equipped with a water cooling system.

“The LCLS-II project got a flying start, profiting from Berkeley Lab’s experience designing and running this unique electron source,” said SLAC’s John Galayda, who until recently led the LCLS-II project. “It continues to be a great collaboration that is crucial in building the next-generation X-ray laser.”

Another challenge is the laser system, said Sasha Gilevich, SLAC engineer in charge of the LCLS-II injector laser.

“To produce electrons efficiently, we want to shine ultraviolet light onto the photocathode, but there is no commercial laser system capable of providing UV pulses with the unique properties required by LCLS-II at the rate of a million pulses per second,” she said. “Instead, we send the light of an infrared laser through an optical system containing non-linear crystals that convert it into ultraviolet light. But because of the heat generated in the crystals, doing this conversion at such a high pulse rate is very demanding, and we’re still in the process of optimizing our system for the best performance.”

A crane lowers the LCLS-II electron gun into the X-ray laser’s accelerator tunnel at SLAC. (Dawn Harmer/SLAC National Accelerator Laboratory)

New electron source, new challenges

LCLS-II’s unique capabilities will also rely on a high-efficiency photocathode to produce the initial electron burst. It consists of a flat disc – merely tens of nanometers thick and a centimeter in diameter – of a semiconductor mounted on a metal support. This allows the electrons to be produced about 1,000 times more efficiently than with the copper cathode used previously.

But the advance comes with a trade-off, said SLAC accelerator physicist Theodore Vecchione: “While the copper cathode lasted for years, the new one is not nearly as robust and may last only a few weeks.”

That’s why Vecchione has been tasked with setting up a facility at the lab to fabricate a stockpile of cathodes, which cannot be simply purchased off the shelf, and to make sure the LCLS-II cathode can be replaced whenever needed.

Now that the injector has generated its first electrons, the commissioning team will spend the next few months optimizing the properties of the electron beam and automating the injector controls.

However, it won’t be until next year, when LCLS-II’s superconducting linear accelerator has been installed, that they will be able to test the full injector, including the short accelerator section that will boost the electron energy to 100 million electronvolts, and get it ready to do its job of generating some of the most powerful X-rays the world has ever seen.

LCLS is a DOE Office of Science user facility.

–Manuel Gnida

More:

- Building a Better Electron Gun

- Berkeley Lab Working on Key Components for LCLS-II X-ray Lasers

- Construction Begins on Major Upgrade to World’s Brightest X-ray Laser

# # #

Founded in 1931 on the belief that the biggest scientific challenges are best addressed by teams, Lawrence Berkeley National Laboratory and its scientists have been recognized with 13 Nobel Prizes. Today, Berkeley Lab researchers develop sustainable energy and environmental solutions, create useful new materials, advance the frontiers of computing, and probe the mysteries of life, matter, and the universe. Scientists from around the world rely on the Lab’s facilities for their own discovery science. Berkeley Lab is a multiprogram national laboratory, managed by the University of California for the U.S. Department of Energy’s Office of Science.

SLAC is a vibrant multiprogram laboratory that explores how the universe works at the biggest, smallest and fastest scales and invents powerful tools used by scientists around the globe. With research spanning particle physics, astrophysics and cosmology, materials, chemistry, bio and energy sciences and scientific computing, we help solve real-world problems and advance the interests of the nation.

The Office of Science is the single largest supporter of basic research in the physical sciences in the United States, and is working to address some of the most pressing challenges of our time. For more information, please visit science.energy.gov.