Adapted from SLAC news release by Glennda Chui

Transitioning to a clean hydrogen economy will require cheaper, more efficient ways to use renewable sources of electricity to break water into hydrogen and oxygen. But a key step in that process, known as the oxygen evolution reaction, has proven to be a bottleneck. Today it’s only about 75% efficient, and the catalysts used to accelerate the reaction, like platinum and iridium, are rare and expensive.

To address these issues, an international team led by scientists at Stanford University and SLAC National Accelerator Laboratory developed a suite of advanced tools, including a new apparatus at Berkeley Lab’s Advanced Light Source (ALS) that enables X-ray microscopy of catalysts under working conditions. The results were published recently in Nature.

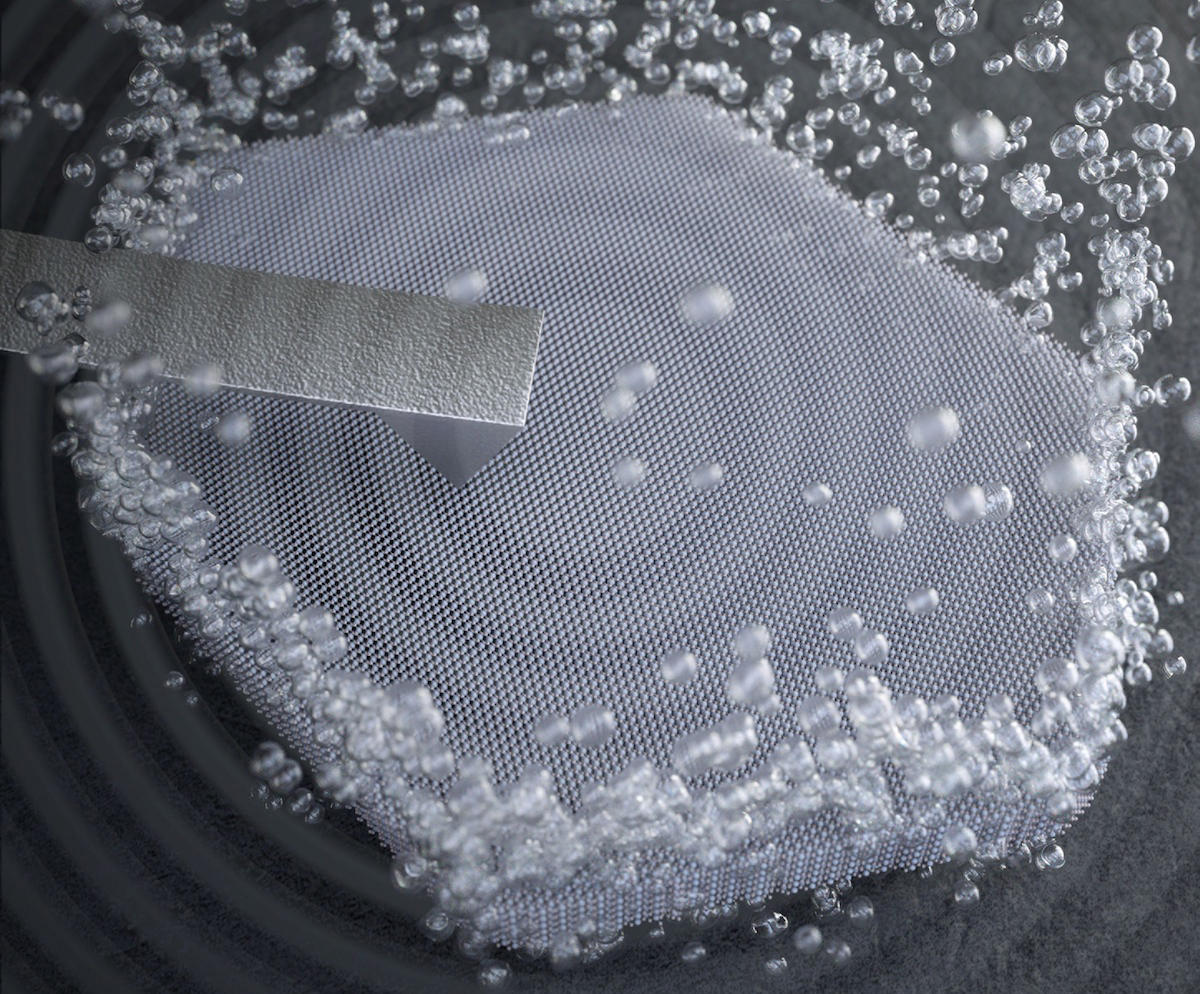

The full suite of techniques, which also included electrochemical atomic force microscopy and scanning electrochemical cell microscopy, allowed the researchers to zoom in on tiny, six-sided nanoparticles of the catalyst, cobalt oxyhydroxide, and watch them accelerate the generation of oxygen.

At the ALS, an electrochemical flow cell was integrated into an X-ray beamline used for scanning transmission X-ray microscopy (STXM). This allowed the researchers to map out the oxidation state of the working catalyst – a chemical state associated with catalytic activity – in areas as small as about 50 nanometers (50 billionths of a meter) in diameter.

The researchers discovered that most of the catalytic activity occurred at the particle edges, and they were able to observe the chemical interactions between the particle and the surrounding liquid at the nanometer scale as they turned up the voltage to drive the reaction. Combining their observations with prior computational work, they were able to identify a single step in the reaction that limits how fast it can proceed.

“This suite of methods can tell us the ‘where, what, and why’ of how these electrocatalytic materials work under realistic operating conditions,” said Tyler Mefford, a staff scientist with Stanford and the Stanford Institute for Materials and Energy Sciences (SIMES) at SLAC who led the research. “Now that we have outlined how to use this platform, the applications are extremely broad.”

More: